TR1-6D Pro Combi

Advanced Compact Handheld Radio Control (6 Buttons)

Heading #2 | Heading #2 |

|---|---|

Product | TR1-6D Pro Combi |

Dimension |

156x65x49mm (TX) / 241x90x70mm (RX1) / 160x90x65.8mm (RX2) |

Weight | 215g (TX) / 390g (RX1) / 255g (RX2) |

Material | Fibre-reinforced plastic |

Heading #2 | Heading #2 |

|---|---|

Pushbutton | 6 Double Step (6D) |

Transmitter Power | AA size battery x 2 |

Receiver Power | Hi: AC 28-456V ; Lo: DC 10-60V |

Frequency | 433/434 MHz |

Emission Power | <10 mW |

e-Card | Yes |

Operating Range |

Up to 100 meters |

Heading #2 | Heading #2 |

|---|---|

Operating Temp. | -30°C ~ +85°C |

ID Code | 4.3 billion (32 Bits) |

IP Rating | TX: IP67 / RX: IP66 |

Selector Switch |

N/A |

Button Lock | Yes |

Flexible Common Terminal (FCT) | Yes |

Relay Module Expansion | Yes |

Heading #2 | Heading #2 |

|---|---|

Pushbutton | 6 Double Step (6D) |

Transmitter Power | AA size battery x 2 |

Receiver Power | Hi: AC 28-456V ; Lo: DC 10-60V |

Frequency |

433/434 MHz |

Emission Power | <10 mW |

e-Card | Yes |

Operating Temp. |

6 Double Step (6D) |

Operating Temp. | -30°C ~ +85°C |

ID Code | 4.3 billion (32 Bits) |

IP Rating | TX: IP67 / RX: IP66 |

Selector Switch |

N/A |

Button Lock | Yes |

Flexible Common Terminal (FCT) | Yes |

Relay Module Expansion | Yes |

TR1-6D Pro Combi Festoon-Free wireless remote systems eliminate the need for traditional wire festooning in overhead cranes by utilizing a pair of receivers. Control signals are sent to the hoist-trolley and bridge control boxes independently, and long runs of festooned wire are no longer needed.

TR1-6D Pro Combi Festoon Free systems are the best solution to modernize the controls of existing cranes. The maintenance costs and down time caused by damaged cable, c-track and other accessories can be avoided using Festoon Free technology. In many cases the cost to repair a damaged festoon will exceed the cost of a festoon free wireless system.

Building new cranes is more cost-effective when they’re designed with festoon free wireless control. Supply power using conductor bar and you’ve eliminated festooned wire altogether. Low lifting clearance and tall, bulky loads are a recipe for disaster with wire festooning—the cable gets in the way and is dragged, snagged, and abused. Cranes with this issue will benefit from the festoon free remote controller with increased productivity and no more downtime due to tangled or damaged festooning.

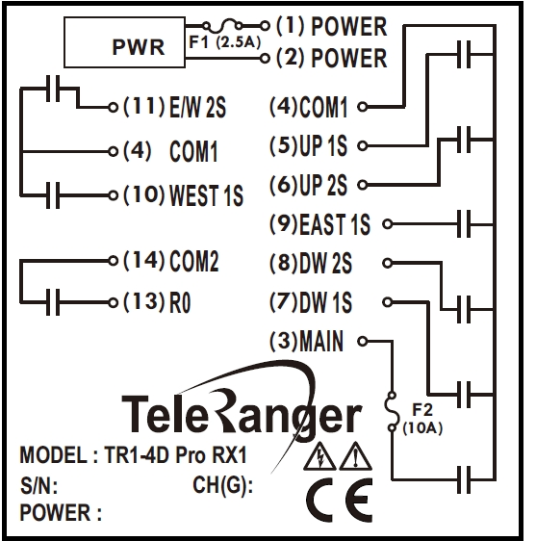

Festoon-Free System Receiver Wiring Diagrams

Festoon free wireless remote controls are also an excellent solution for transfer carts, below the hook attachments, vacuum handling equipment, and bulk grabbers—anywhere a wired connection is impractical or hazardous. Teleranger festoon free systems equipped with 2 or more receivers can control multi hoist cranes, concrete casting equipment and conveyor systems. When a signal must be distributed to multiple pieces of equipment, the Teleranger festoon free system is the solution.

Figure 1. Trolley / Hoist Control Box Receiver Wiring Diagram